Frequently Asked Questions

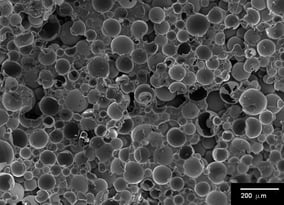

What is Syntactic Foam?

Syntactic foam is a class of material created using pre-formed hollow spheres (commonly made of glass, ceramic, polymer or even metal) bound together with a polymer. The “syntactic” portion refers to the ordered structure provided by the hollow spheres. The “foam” term relates to the cellular nature of the material. Thanks to its unique properties of high strength at low density, syntactic foam has become widely used in subsea buoyancy applications. Syntactic materials are resistant to the combined effect of hydrostatic pressure and long-term exposure which make them ideal for oceaneering projects such as cable and hardball floats and instrumentation support. They also provide strength and structural integrity at a significantly lower weight per volume than most traditional materials which make them an attractive choice in many defense and civil engineering applications. Other examples abound, including MacroCore™, our advanced composite syntactic for demanding core applications. The toughened macrosphere matrix provides far greater stiffness, strength, impact and shock properties than standard core materials. It is ideally suited for composite-to-metal joints, a well-documented area of concern in all composite structures. As a closed cell structure, the core easily processes in all composite applications including vacuum bag, RTM, and pultrusion without increasing overall density.

How Do I Calculate Buoyancy?

The scientific principle of buoyancy is calculated by measuring the weight of fluid displaced by the object in it. An object placed in a fluid displaces a certain amount of the fluid equal to the object’s volume. While the object’s weight pushes down on the fluid (liquid or gas), an upward force is exerted on the object, creating a resistance to gravity. The weight of the fluid is equal to the buoyancy force acting upon the object.

As a typical example, one might want to know how much syntactic foam would be required make 100 lbs of steel neutrally buoyant in seawater.

First you would need to know how much the steel “weighs” in water. This is calculated by the simple equation of:

Weight in Sea Water = (Density of Sea Water – Density of Steel) x Volume of Steel

For our example, we’ll assume a Sea Water density of 64.0 lbs/ft3 and a Steel density of 495 lbs/ft3,

This means our 100 lbs of steel has a volume of 0.202 ft3.

Our water weight then becomes:

Weight in Sea Water = (64.0 – 495) x 0.202 = – 87.06 lbs

This means we would need to provide 87.06 lbs of lift to make the steel neutrally buoyant. If we used a 24 lb/ft3 syntactic foam we can plug into the same equation to solve for the volume:

Weight in Sea Water = (Density of Seawater – Density of Syntactic) x Volume of Syntactic

87.06 = (64.0 – 24.0) x Volume of Syntactic

2.177 ft3 = Volume of Syntactic

Any volume of syntactic greater than this and the structure would become buoyant and float. Any less and the combination would sink.

How Do I Machine Syntactic Foam?

Please Click Here to view our Machining Guide.

What Densities are Available for ESS Syntactic Foam?

Please Click Here to view our Density Chart.