Syntactic Buoyancy Materials

Subsea Buoyancy Materials

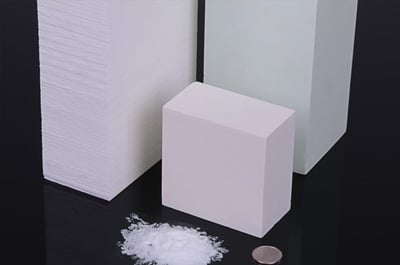

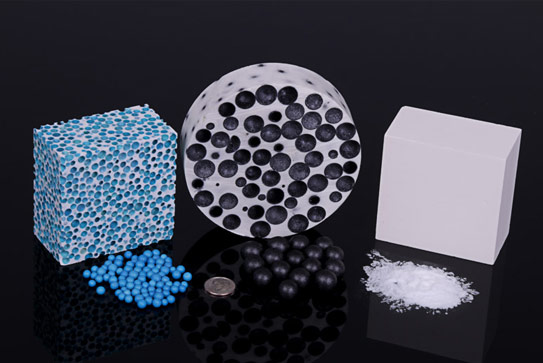

ESS syntactic foams are engineered to provide the lowest possible density for any given depth. Produced from the most advanced resin and hollow glass microspheres available, they offer high compressive strength and stiffness, high buoyancy per volume and extremely low water absorption – from the surface to subsea depths greater than 10,000 meters. Available in a range of densities, these lightweight foams meet the depth and buoyancy requirements for a variety of subsea and oceanographic applications such as: buoys, floats and both manned and unmanned undersea vehicles.

The full range of ESS materials are available as blocks or sheets and can be delivered with various grades of customization. Standard blocks can be easily machined into almost any shape or bonded to form larger structures, giving designers a high degree of flexibility. ESS also offers a variety of machining services and finishing options including: parts to print, protective composite outer skins, urethane coating and marine grade paints and finishes. To further ensure that customers get the optimal buoyancy solution for their application, custom-made tooling can be used to manufacture specific syntactic foam sizes and geometries.

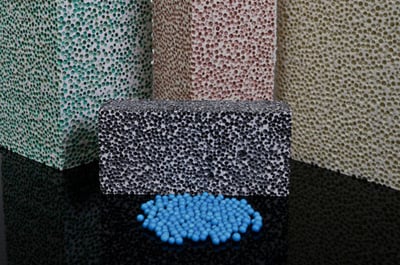

ESS manufactures two distinct versions of subsea syntactic foam: Microsphere and Macrosphere.

Macrosphere syntactic foam is ideal for the fabrication of larger and custom structures. It also attains lower densities in certain applications, providing lower cost buoyancy for a given depth.

The full range of ESS materials are available as blocks or sheets and can be delivered with various grades of customization. Standard blocks can be easily machined into almost any shape or bonded to form larger structures, giving designers a high degree of flexibility. ESS also offers a variety of machining services and finishing options including: parts to print, protective composite outer skins, urethane coating and marine grade paints and finishes.